Hot Gas Filtration

Hot Gas Filtration

Global air emission limits and regulations are becoming ever stricter. Many companies are facing the challenge of trying to reduce emissions to meet legal requirements and to reduce their impact on the environment.

Macrotec’s Hot Gas Filters can be used on incinerators, cremators, biomass boilers, mineral processing applications, and other industrial processes for the removal of particulate matter (dust) to below 5 mg/m³. Dry Gas Scrubbing can be added for the removal of acid gasses, dioxins, and heavy metals. Our filtration systems utilise ceramic filters for the highest removal efficiencies while also having the highest operating temperatures. This, coupled with low maintenance and a modular design which ensures ultimate redundancy, means our Filtration systems are hard to beat.

Certification

Macrotec is certified to the following standards:

ISO 9001:2015 | Quality Management Systems

ISO 14001:2015 | Environmental Management Systems

ISO 45001:2018 | Occupational Health & Safety Management

What is Hot Gas Filtration?

Multiple industrial processes produce emissions, containing products which are hazardous to people’s health, or pollute the environment. Most countries have instituted regulations that limit these emissions, requiring these gasses to be cleaned prior to release into the environment.

Since these gasses often reach several hundred degrees, conventional bag-type filters will fail quickly due to the high temperatures, leaving Ceramic Filtration as the only long-term reliable option.

Particulate Matter often consists of fine particles (PM 2.5 and PM 10), which are extremely harmful to human health. PM 2.5 and PM 10 is unfortunately able to pass through many conventional filters, however Ceramic Filtration offers a reliable method of capture.

Dry Gas Scrubbers are used in conjunction with Ceramic Filters to either adsorb or neutralise other harmful products, such as hydrogen chloride (HCl), sulphur dioxide (SO₂), hydrogen fluoride (HF), lead (Pb), mercury (Hg), and Dioxins and Furans (PCDD/PCDF).

How does Hot Gas Filtration work?

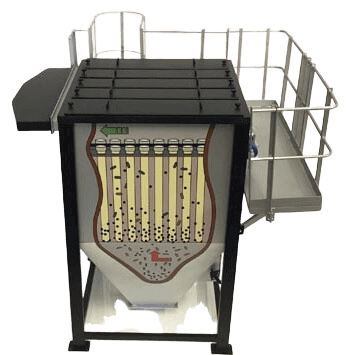

Our filtration units work by drawing the flue gas through hollow ceramic filter elements, capturing particles on the filter wall. The fine structure of the filter elements mean it is able to capture particles as smell of 2.5 PM.

The filtration unit is split into “dirty” and “clean” compartments, with the flue gas entering on the “dirty” side and particulate matter being captured on that side of the filter element. Clean air then passes from the filter element into the “clean side” and out to the stack.

The filter elements are periodically cleaned down with reverse pulse cleaning using compressed air, discharging the built-up particles to a collection bin.

Advantages of Ceramic Filtration

- Ceramic elements can withstand temperatures of up to 1,000°C, compared to 140°C to 180°C for bag filters.

- Ceramic elements are non-flammable.

- Ceramic elements are resistant to acids and alkalis.

- Operating temperature of up to 450°C, allowing for scrubbing at the most efficient temperatures and almost all processes.

- No need for reaction towers or cyclones.

- Lowest emission level achieved, with constant and reliable performance.

Our Ceramic Filter Elements

The key to Macrotec’s filters is our filter elements, which are designed and manufactured by Glosfume. These elements are able to operate at temperatures of up to 1,000°C, at a 99.99% efficiency, and are able to remove sub-micron particles.

For optimum performance and reliability, all Glosfume filter elements are formed from engineered fibres using a fully automated process. During manufacture, forming times and pressures are strictly maintained to achieve stable pressure drop and bulk density. Every tenth element manufactured is tested and recorded, then packed in bar coded packaging to ensure complete traceability.

For the best possible performance, each element is fully machined to strict tolerances. A specially formed surface allows dust to form a conditioned layer that assists the removal of submicron particles. Gas flow is improved, and more evenly distributed, by the unique tapered profile of each element. The taper makes it easier to clean the filter element.

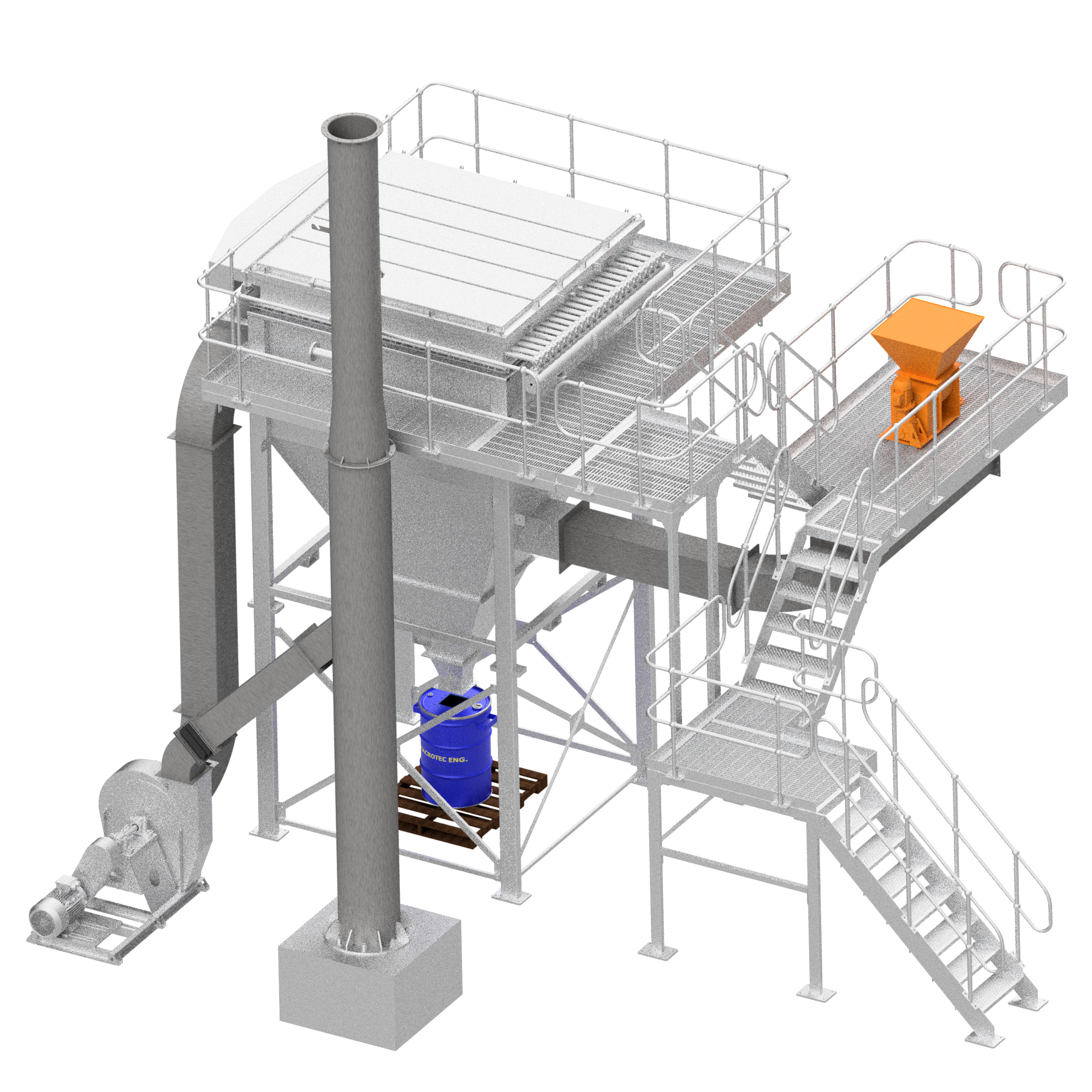

Isometric View: Full Filtration Assembly

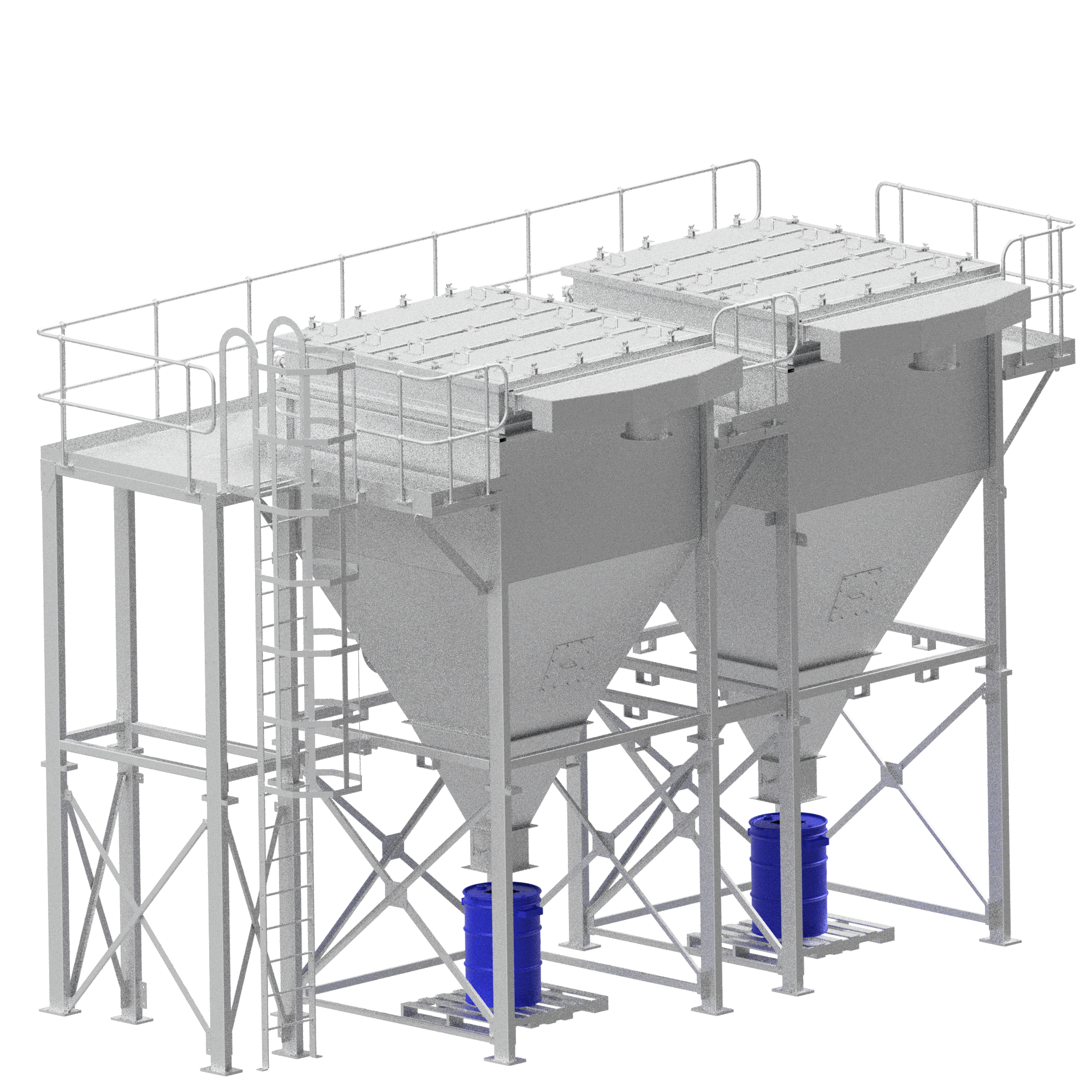

Isometric View: Dual Filters