Best practices for incineration

This section discusses best practices for incineration, which can lead to substantial reductions in the formation, emission and exposure to toxic substances from waste incineration.

Waste reduction

Waste reduction reduces the volume and toxicity of materials for incineration (or other treatment option), thus decreasing incinerator use, emissions and the resulting health and environmental risks. For example, incineration might be reserved for only the most dangerous types of waste, e.g., contaminated sharps. Waste reduction can substantially lower demands for incineration and provide other important benefits, e.g., greater environmental protection, enhanced occupational safety and health, cost reductions, reduced liability, regulatory compliance, and improved community relations (HCWH 2001).

As mentioned, extensive reviews of waste reduction have been provided elsewhere (HCWH 2001; 2002; WHO 1999). General approaches include source reduction, material elimination, recycling, product substitution; technology or process change, use of good operating practices, and preferential purchasing. Hospitals and other facilities have many opportunities to minimize waste, including:

- Segregating wastes. This requires clearly marked and appropriate containers, staff training to separate various wastes (health-care waste, hazardous waste such as mercury, low-level radioactive waste, and regular trash), minor maintenance infrastructure (containers, suitable space) and management

Studies in Nigeria and Benin show that health-care waste is either not segregated or insufficiently segregated (Adama 2003). The same study shows that policies and action plans are not sufficient or not comprehensive enough to address this problem.

- Reducing unnecessary injections (as much as 70% of all injections may be unnecessary) (Gumodoka et , 1996).

- Recovering silver from photographic

- Eliminating mercury products and mercury-containing

- Buying PVC-free plastic

- Treatments to remove and concentrate waste, e.g., filters and traps to remove mercury from

Effective waste reduction programs require commitment of top management and effective communication among hospital staff. Physicians, other medical staff and managers must be made aware of waste generation and associated hazards. Source reduction requires involvement of purchasing staff and periodic reassessment. These programs require staff and moderate infrastructure support, planning and organization, assessment, feasibility analysis, implementation, training, and periodic evaluation. A waste audit will generally be helpful.

Design

Proper design and operation of incinerators should achieve desired temperatures, residence times, and other conditions necessary to destroy pathogens, minimize emissions, avoid clinker formation and slagging of the ash (in the primary chamber), avoid refractory damage destruction, and minimize fuel consumption. Good combustion practice (GCP) elements also should be followed to control dioxin and furan emissions (Brna and Kilgroe 1989). Table 2 provides recommendations for small-scale intermittent incinerators.

It appears that the temperature, residence time and other recommendations in Table 2 are rarely achieved by small-scale incinerators. Additionally, as mentioned earlier, few small-scale units utilize air pollution control equipment.

Siting

The location of an incinerator can significantly affect dispersion of the plume from the chimney, which in turn affects ambient concentrations, deposition and exposures to workers and the community. In addition to addressing the physical factors affecting dispersion, siting must also address issues of permissions/ownership, access, convenience, etc. Best practices siting has the goal of finding a location for the incinerator that minimizes potential risks to public health and the environment (EPA 1997). This can be achieved by:

- Minimizing ambient air concentrations and deposition of pollutants to soils, foods, and other surfaces, e.g.,

- Open fields or hilltops without trees or tall vegetation are preferable. Siting within forested areas is not advisable as dispersion will be significantly

- Valleys, areas near ridges, wooded areas should be avoided as these tend to channel winds and/or plumes tend to impinge on elevated surfaces or downwash under some

- Minimizing the number of people potentially exposed, g.,

- Areas near the incinerator should not be populated, e.g., containing housing, athletic fields, markets or other areas where people

- Areas near the incinerators should not be used for agriculture purposes, e.g., leafy crops, grasses or grains for

Appropriate sizes for buffer surrounding incinerators are based on dispersion modeling (Section 6.4.5). For typical small-scale units, especially if nighttime operation may occur, a 500 to 750 m buffer surrounding the facility is advisable to achieve dilution ratios above 1000. During the day, a 250 m buffer should obtain the same dilution ratio. These distances are based on ideal conditions, e.g., relatively flat and unobstructed terrain.

Table 2

Recommendations of key design/operating parameters for small-scale intermittent incinerators.

Derived in part from EPA (1990), UNDP (2003), and De Montfort literature.

| Capacity | Destruction rate, safety boxes capacity | District/subdistricts in Taylor (2003) that regularly used incinerators destroyed an average of 58 safety boxes per month, about 14 per week, equivalent to ~12 kg/week. Remote areas may only generate 1 kg per month. Proper sizing is important. Ideally, unit should burn for long periods (~4 hrs) to save fuel. (De Montfort units are not suitable for short sharp burns without a warm up period, though this appears to be common practice). |

| Temperatures | Primary chamber Secondary chamber Gas entering air pollution control devices, if any | 540 to 980 C 980 to 1200 C (EPA 1990 recommendations) >850/1100* C (S. African and EU standards) >1000/1100* C (Indian and Thai standards) * more than 1% chlorinated organic matter in waste <230 C |

| Residence times | Gas (secondary chamber) | >1 s |

| Air flows | Total combustion air Supply and distribution of air in the incinerator. Mixing of combustion gas and air in all zones. Particulate matter entrainment into flue gas leaving the incinerator | 140 – 200% excess Adequate Good mixing Minimize by keeping moderate air velocity to avoid fluidization of the waste, especially if high (>2%) ash waste is burned. |

| Controls & Monitoring | Temperature and many other parameters | Continuous for some, periodic for others |

| Waste | Waste destruction efficiency Uniform waste feed Minimizing emissions of HCl, D/F, metals, other pollutants Load/charge only when incinerator operating conditions are appropriate | >90% by weight Uniform waste feed, and avoid overloading the incinerator Avoid plastics that contain chlorine (polyvinyl chloride products, e.g., blood bags, IV bags, IV tubes, etc. Avoid heavy metals, e.g., mercury from broken thermometers etc. Pre-heat incinerator and ensure temperatures above 800 C. Avoid overheating. |

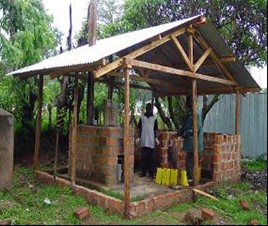

| Enclosure | Roof | A roof may be fitted to protect the operator from rain, but only minimum walls. |

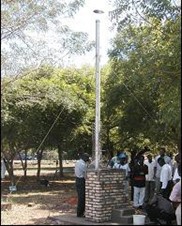

| Chimney | Height | At least 4 – 5 m high, needed for both adequate dispersion plus draft for proper air flow |

| Pollution control equipment | Installing air pollution control devices (APCD) | Most frequently used controls include packed bed, venturi or other wet scrubbers, fabric filter typically used with a dry injection system, and infrequently electrostatic precipitator (ESP). Modern emission limits cannot be met without APCD. |

In practice – and in contrast to the guidelines above – incinerators usually are located within 10 to 30 m of clinics/hospitals for reasons of convenience, management, etc., and they often are located adjacent to or within populated areas. Several cases of incompatible siting are documented in Figure 5.

Figure 5

Photos indicating siting problems due to proximity to populated areas or poor dispersion potential.

Left: children’s park next to the incinerator at Kulathummel Salvation Army Hospital, India (WHO, taken from HCWH 2002);

Center: unknown, reported in Adama (2003);

Right: Kenya, reported in Adama (2003).

Construction

Adequate plans, drawings, and quality control are necessary to construct incinerators. Dimensional drawings, tolerances, material lists, etc. are necessary.9 The Kenya survey (Taylor 2003) indicates a lack of adequate quality control in the construction phase, resulting in incorrectly-built facilities. Further, shelters, protective enclosures, and pits have not been constructed at most sites.

Operation

General operating (prior and following loading)

Proper operation is critical to achieving design parameters. In general, the manufacturer or designer of the equipment should provide a manual that discusses operating practices including startup procedures, shutdown procedures, normal operation, troubleshooting, maintenance procedures, recommended spare parts, etc. These will be equipment-specific. Some general operation issues are listed in Table 3.

Table 3

Operation and maintenance issues for small incinerators.

| Waste selection | Restricted wastes |

| Waste-feed handing | Volume, moisture |

| Incineration operation, monitoring and control | Recharge, fuels, temperature |

| Air pollution control systems, if any | Filters |

| Maintenance | Hourly, weekly, monthly, annual, control equipment |

| Control and monitoring instrumentation | Temperature, pressure, smoke/opacity |

| Recordkeeping | Operating records, maintenance records |

| Safety | Infection control during waste handling, equipment safety, fire safety |

EPA (1990) has a thorough guide to operating procedures for hospital waste incinerators, including small batch and intermittent units. While not all sections of the guide are relevant to low cost small- scale incinerators that lack monitoring, automatic controls and other features, many aspects are very relevant, thus, portions of this guide have been reproduced in Appendix C. A guide specifically tailored to the De Montfort incinerator is under development (T. Hart, personal communication, Dec. 15, 2003). The De Montfort incinerator reports and web site also makes several recommendations:

- The incinerator must be fully heated up before wastes are added, requiring about 30 min or longer, depending on ambient temperature, type of fuel, fuel moisture content, etc. However, most of the 14 small-scale units surveyed in Kenya (Taylor 2003) were not being operated in this fashion, rather, safety boxes were loaded prior to

- Firewood must have a low moisture content (<15%)

- Temperature monitors are not used, thus there is no indication that suitable temperature have been

- Grey or black smoke indicates poor combustion and low

- Low cost dial type readout temperature sensors should be available for a reasonable cost and it is strongly suggested that units incorporate a quantitative temperature gauge, and that waste only be combusted when the temperature is in the correct

- Manual operation requires the constant presence of an operator when burning Dry fuels must be added every 5 – 10 min.

- Flame must not be extinguished during

- Grates must be regularly checked and raked to keep

Waste loading/charging

- Proper amount of fuel should be present (2/3 full) before adding wastes

- Operator care, judgment, and experience necessary to deal with different load types

- One safety box every 10 minutes appears to be an optimal rate for charging the De Montfort

- Very wet loads should be separated with drier material, and in extreme case supplemented by an extra increment of diesel/kerosene.

- High heat fuels (plastics, paper, card and dry textiles) helpful to maintain temperature

- Waste mixing is desirable. Mixing may be possible by separating waste types at the source in bags, labeling each, and loading in appropriate combination or

- Operators should not sort and mix waste prior to incineration due to

- Supplemental fuel may be need for wastes with a high moisture content or low fuel

- Restricted wastes should never be burned, including radioactive wastes, mercury thermometers, or hazardous

- Because of the lack of emission controls, wastes containing chlorine, sulfur, nitrogen and toxic metals should be

- Measures may be necessary to hold wastes in position long enough to burn and to prevent them from failing through grate without being destroyed. This is especially important for smaller wastes, e.g., pills, sharps, etc. Straw or wood may be used to hold safety boxes in Sharps should be mixed with other waste.

- When the loading door is closed or opened rapidly, burning gases may come through the under air ports (air holes).

- Possible operator exposure due to smoke, flames, heat when loading door is opened or rapidly shut

- The operator should open the door while standing at the front of the incinerator (to protect from blowback), wait a few seconds for any blowback to subside, and load from the side.

Burndown/cooldown

- Sufficient time must be provided for the ‘fixed carbon’ in the waste bed to combust. A recommended period is 1 hr plus an additional 20 min for each hour of operation or typically 2 to 5 hr total (EPA 1990), but this will depend on many

Monitoring

Combustion and emission monitoring is used routinely for several purposes, including determining whether incinerators are properly operated. Additionally, monitoring is used to assure compliance with regulatory limits and, to an extent, to help build public trust. Monitoring may be classified into the following categories:

- Sensory observations, e.g., visual assessment of stack emissions or assessment of odors. This is similar to methods practiced 30 or (many) more years ago. Sensory monitoring is clearly unable to detect many emissions of concern, and is very

- Stack tests, e.g., measurement of emissions for brief periods of time. Stack testing started in the 1970s, and is still widely used for special tests (dioxins, metals, etc.) These tests are expensive, and provide emission data for only a brief period of time that may not be

- Continuous emission monitoring (CEM), g., in-stack monitoring of opacity (particle surrogate), SO2, CO, O2, NOx, HCl and recently Hg is regularly conducted at modern incinerators. CEM is required for larger incinerators. Continuous monitoring of temperature and other parameters (e.g., pressure drop across filters) is also used (and often required). CEM data have been used as surrogates of emissions and to indicate the suitability of combustion conditions, although there are issues, e.g., correlation of CO to products of incomplete combustion (PICs) is poor at low CO levels.

- Environmental monitoring. While used infrequently, monitoring of ambient air, soil, food, , around incinerators has been used to confirm predictions of multimedia exposure models.

Low-cost and locally-built incinerators have minimal if any capability to monitor operations, including emissions or combustion conditions, other than the use of sensory observations. It is suggested that operators might never know that they are properly operating the incinerator without a temperature gauge and more training (described below).

Safety

Safety considerations include prevention of infection, equipment safety (to prevent operator injury), and fire safety. Some specific recommendations include:

- Eye protection and a face mask should be worn when opening loading door or visually checking the unit to protect against glass shards from exploding ampoules and glass

- Heavy-duty gloves and apron should be worn when handling health-care

- Ash must not be handled by

- An adequate cool-down period (3 to 5 hrs) is necessary before ash

- Appropriate disposal of ash is necessary.

Maintenance

Safety considerations include prevention of infection, equipment safety (to prevent operator injury), and fire safety. Some specific recommendations include:

Regardless of how well equipment is designed, wear and tear during normal use and poor operation and maintenance practices will lead to the deterioration of components, a resultant decrease in both combustion quality, an increase in emissions, and potential risks to the operator and public. Operation and maintenance also affect reliability, effectiveness and life of the equipment. Essentially all components of small-scale incinerators are prone to failure and require maintenance. Maintenance on an hourly to semi-annual schedule is required (EPA 1990). A typical maintenance/schedule for a small-scale incinerator is shown in Table 4.

Table 4

Typical maintenance schedule for incinerators (derived in part from EPA 1990).

| Hourly | Ash removal | Inspect and clean as required |

| Daily | Temperature, pollution monitors Underfire air ports Door seals Ash pit | Check operation Inspect and clean as required Inspect for wear, closeness of fit, air leakage Clean after each shift |

| Weekly | Latches, hinges, wheels, etc. | Lubricate if applicable |

| Monthly | External surfaces of incinerator and chimney (stack) Refractory Upper/secondary combustion chamber | Inspect external hot surfaces. White spots or discoloration may indicate loss of refractory Inspect and repair minor wear with refractory cement Inspect and remove particulate matter accumulated on chamber floor |

| Semi-annually | Hot external surfaces Ambient external surfaces | Inspect and paint with high temperature paint as required Inspect and paint as required |

For small-scale low cost incinerators, components particularly prone to failure that are mentioned in several reports include (Taylor 2003; HCWH 2002):

- Firebox access doors and frames that warp, hinges that seize and break, and assemblies that break free of

- Grates that distort, break, or become

- Chimneys (stacks) that are badly corroded and chimney supports (guy wires) that are not adequately attached, broken, loose or

- Masonry, bricks and particularly mortar joints that

- Grills that are damaged or

- Steel tops that warp and short-circuit the secondary combustion

De Montfort incinerators typically require major maintenance after 3 years, costing approximately 70% of initial construction costs (Taylor 2003). Funds must be made available to provide for both routine and major maintenance. The use of service contracts may be appropriate.

Facility inspection

As currently used, stack gases or necessarily even basic combustion process parameters like temperature are not monitored in small-scale incinerators. There is a need for even basic facility inspections to ensure that the unit is in proper repair and that compliance with best operating practices is feasible (Kentucky 1996). Facility inspections should include:

- Visual inspections of the facility for corrosion, leaks, mortar and seal failures,

- Testing of doors and other moving

- Regular schedule, g., monthly to quarterly.

- Documentation of use, maintenance, and

- Reporting of findings to higher

A trained operator can provide this inspection, however, an independent assessment would provide greater independence and impact. Ideally, a governmental Environmental Health Officer or Air Pollution Control Specialist, along with the certified operator, would conduct an inspection twice per year.

Record keeping

Records must be maintained for maintenance activities to prevent premature failure of equipment, increase life, track performance, evaluate trends, identify potential problems areas, and find appropriate solutions. In current practice, few if any records are maintained.

Training and management

General duties

Proper operation of incinerators is necessary to minimize emissions and other risks. Only a trained and qualified operator should operate or supervise the incineration process. The operator must be on- site while the incinerator is operating. Without proper training and management support, incinerators cannot achieve proper treatment and acceptable emissions, and the resultant risks due to incineration can greatly increase and may be unacceptable. Based on the Kenya survey (Taylor 2003), training and the commitment to training is inadequate and represents and important factor in the poor adoption of small-scale incinerators. The same report indicates that operator training is the first and foremost need. A certification process for operators and supervisors is suggested below.

Operating and maintenance manual

The manufacturer or designer of the incinerator should provide operation and maintenance manuals that provide specific instructions for their equipment translated to the local language. These manuals should be incorporated into a best practices guide for each type or version of incinerators

Operator certification

Operator certification following a defined process is suggested to ensure proper operation and use to minimize emissions and other risks associated with incinerator. Additionally, proper operation and maintenance will improve equipment reliability and performance, prolong equipment life, and help to ensure proper ash burnout (EPA 1990).

Typically, certification involves both classroom and practical training.

Adequate classroom training is demonstrated by the completion of an approved training program. An approved program would include the following components:

- Coverage of the following:

- Fundamental concepts of incineration

- Risks associated with health-care waste and waste incineration

- Waste reduction, segregation and handling goals and practices

- Design, operation, maintenance of the specific incinerator used

- Operation problems and solutions (e.g., white smoke, black smoke, )

- Operator safety and health issues

- Community safety and health issues

- Best practices guide for the specific equipment including appropriate fuels, frequency of burns, etc. This will need to be tailored to both the equipment plus waste stream at the

- Inspection and permitting

- Record keeping (operation and maintenance activities)

- At least 24 hours of classroom

- An exam created and given by the course

- Reference material covering the course given to the students

Practical training is necessary in addition to classroom training. Practical training can be obtained by demonstration that the operator has either:

- Operated an incinerator for six

- Supervised a qualified incinerator operator for six

- Completed at least two burn cycles under the supervision of a qualified.

Regulations affecting incinerators

Emission limits

Emission limits are applicable to a best practices guide. Emission factor–based estimates for controlled air incinerators without air pollution control equipment (AP42, EPA 1995) are shown for comparison.

- The US EPA promulgated emission limits for incinerators under the 1997 “Standards of Performance for New Stationary Sources and Emission Guidelines for Existing Sources: Hospital / Medical / Infectious Waste Incinerators” (EPA 1997). All existing incinerators were to be in full compliance by September The US EPA also subjects new incinerators to a 5% visible emission limit for fugitive emissions generated during ash handling, a 10% stack opacity limit, and other restrictions.

- Standards vary by incinerator capacity and whether it is an existing or new

- The standard setting process is based largely on the best performing units in the mid- 1990s, thus the basis of the standards is technical feasibility and cost-effectiveness. However, to site and permit a facility, local authorities may require health risk

- EU limits were promulgated in 2000 (CEC 2000). Periodic tests are required to ensure standard

- Standards are based in on the fifth Environment Action Programme: Towards Sustainability, a European Community programme of policy and action in relation to the environment and sustainable development, supplemented by Decision No 2179/98/EC that require that critical loads and other limits on nitrogen oxides, sulfur dioxide, heavy metals and dioxins should not be exceeded, with the goal of public health protection. Additionally, this program set goals of 90% reduction of dioxin emissions of identified sources by 2005 (1985 level), and 70% reduction for cadmium, mercury and lead emissions in 1995. For dioxins, the EU standard reflects the protocol on persistent organic pollutants signed by the EC within the framework of the UN Economic Commission for Europe (UN-ECE) Convention on long-range transboundary air pollution that contains legally binding limit values for dioxins and furan emissions (0.1 ng TEQ/m3 for installations burning more than 3 tons/hr of municipal solid waste, 0.5 ng/m3 for incinerators burning more than 1 ton/hr of medical waste, and 0.2 ng TEQ/m3 for installations burning more than 1 ton/hr of hazardous

- The final directive (CEC, 2000) applies to all size ranges (size classes in earlier versions of the directive were removed).

- WHO has not developed a guideline value for emissions from a single source such as:

Existing regulatory limits show considerable divergence for particulate matter, dioxin/furans and several metals, in part a result of the different means used to set standards.

The AP42 emission factor estimate for PCBs in Table 5 is striking. (AP42 is not a standard, but a compilation of emission data.) Published data on PCB concentrations in incinerator discharges are sparse, and emissions can vary considerably between incinerators. In general, concentrations of dioxin-like PCBs to contribute a minority of the total dioxin toxic equivalents. Neither US nor EU standards control PCB-TEQs, though the FAO/GAO provisional intake guideline value does include co-planar PCBs.

Incinerators generally cannot meet modern emission standards without emission controls.11 For example, Ferraz (2003) determined that dioxin concentrations in combustion gas were 93 to 710 times higher than the (EU) legal limit (0.1 ng TEQ/m3), depending on the waste composition. One new control approach appears very promising, namely, catalytic filter technology that removes dioxins and furans, along with particulate matter. This essentially passive technology can be retrofitted in existing baghouses, typically following water quenching and dry scrubbing, and it appears cost-effective

(Fritsky et al. 2001). However, it is not likely adaptable to small-scale units that do not have exhaust fans, any pollution controls, much less the needed infrastructure.

In summary, small-scale locally-built incinerators appear unlikely to meet emission limits for carbon monoxide, particulate matter, dioxin/furans, hydrogen chloride, and possibly several metals and other pollutants.

Permitting

A permitting program of facilities may be a useful means – and likely the only means – to ensure compliance with best practices guideline. Permitting programs are generally mandatory and would normally include the following:

- Design review: Permitting is a means of ensuring that only acceptable incinerator equipment is constructed and utilized, g., incinerators should utilize a secondary combustion chamber, a chimney of specified height, etc.

- Safe operation: Penalties or shut-down for repeated noncompliance of best practices guidelines should be

- Maintenance: Regular inspections are required to ensure adequate

- Operator certification: Training of the operator(s) and supervisory personnel must be

- Inventory and record keeping: Authorities should inventory incinerator facilities and track.

Global conventions

The final version of the Stockholm Convention on Persistent Organic Pollutants (POPs) was adopted in May 2001 and is now in the process of ratification. Annex C deals with the unintended production of POPs, which include dioxins and furans. The Convention specifically targets incinerators. Among other actions, it will require counties to develop and implement actions to address the release of dioxins and furans; Article 5 will require measures to reduce dioxin/furan releases from incinerators with the goal of their “ultimate elimination;” and countries are required to promote the use of alternatives including the use of the best available techniques/technologies.

Under the Stockholm Convention, incinerators are not a preferred technique due to their potential to emit POPs. Only highly controlled incinerators with air pollution control equipment and operational practice specifically designed to minimize dioxin formation and release could be considered the best available technology.

Emission standards for small-scale incinerators

It is not recommended that WHO develop or specify emission standards or guidelines for small-scale incinerators. Such standards require quantitative emission limits on each type of pollutant, and standards require the use of inspection, testing, monitoring and certification programs for incinerators and operators to ensure compliance. Small-scale low cost incinerators will not meet modern emission standards for many pollutants, e.g., carbon monoxide, particulate matter, dioxin/furans, hydrogen chloride, and possibly several toxic metals. To meet emission standards, incinerators must be designed to use air pollution control equipment (removing particles, acid gases, etc.), combustion process monitoring (temperature, flow rates, etc.), and process controls (waste, fuel, air flows). Few of these technologies are adaptable to small-scale low cost incinerators that do not have exhaust fans, pollution controls, dampers, monitoring, electrical power, etc. These technologies will greatly increase the cost and complexity of incinerators, and they are unlikely to perform reliability in many settings given the need for careful operation, regular maintenance, and skilled operators.

Where incineration is used, national governments might utilize emission limits and other requirements to ensure effective waste treatment, minimize emissions, and decrease exposure and risks to workers

and the community. This should include the use of approved incinerator designs that can achieve appropriate combustion conditions (e.g., minimum temperature of 800 C, minimum chimney heights); appropriate siting practices (e.g., away from populated areas or where food is grown); adequate operator training (including both classroom and practical training); appropriate waste segregation, storage, and ash disposal facilities; adequate equipment maintenance; managerial support and supervision; and sufficient budgeting.

Exposure and health risks from incineration.

Health risk assessment framework

The objective of HRA is to estimate effects of incinerator emissions, in this case, air pollutants, on human health, including short-term acute impacts (systemic diseases) and chronic (long-term) impacts (e.g., cancer). The goal generally is to assess the overall risk associated with exposure to emissions, e.g., the ‘risk’ quantified as the probability of harm, the fraction of the population potentially affected, and/or the number of cases of disease.

Historically, health concerns raised by incineration focused on communities living near the incinerator. More recently and rather definitively, the NRC (1999) identified three potentially exposed populations: (1) the local population, which is exposed primarily through inhalation of airborne emissions; (2) workers at the facility, especially those who clean and maintain the pollution control devices; and (3) the larger regional population, who may be remote from any particular incinerator, but who consume food potentially contaminated by one or more incinerators and other combustion sources that release persistent and bioaccumulative pollutants

The analysis will follow the general steps of hazard assessment, toxicity assessment, exposure assessment, and risk characterization, as summarized below. The assessment is screening in nature, as described below.

Hazard assessment

In hazard assessment, causative agents are identified and the feasibility of linkages and mechanisms between air pollutants and adverse health effects are demonstrated. Much of this has been completed by the development of lists of priority chemicals, regulations, etc.

Dose-response assessment

The dose-response assessment describes the toxicity of the chemicals identified above using models based on human (including clinical and epidemiologic approaches), and animal studies. Dose- response relationships depend on the pollutants:

- Systemic toxicants. Many studies have indicated a threshold or ‘no-effect’ level, that is, an exposure level where no adverse effects are observed in test populations, as cell mechanisms are able to repair or isolate damaged cells. Some health impacts may be reversible once the chemical insult is removed. In this case, a reference dose or concentration, for use in the risk characterization as a component of the hazard

- Both linear and nonlinear dose-response models are used for carcinogens. With linear models, doubling the exposure doubles the predicted risk. Cancer potencies are typically provided for each exposure pathway or for total intake.